Spherical rod end bearings provide a special solution for applications requiring frictionless motion in multiple directions. These bearings utilize a spherical face, allowing the connection to rotate freely within a restricted range of motion. This property makes them ideal for applications where adjustability is paramount, such as in automotive suspension systems, robotics, and industrial machinery.

- Furthermore, spherical rod end bearings tolerate heavy loads successfully.

- They are also protected to dirt and debris, ensuring predictable performance in demanding environments.

By incorporating spherical rod end bearings into your designs, you can maximize motion features while decreasing friction and wear. This ultimately leads to enhanced product performance, boosted lifespan, and reduced maintenance requirements.

Reliable Rod End Bearing Suppliers for Industrial Applications

When your industrial operations demand reliability, choosing the right rod end bearing suppliers is vital. These specialized bearings facilitate smooth and efficient motion in a wide range of applications, from manufacturing equipment to agricultural systems. To achieve optimal performance and longevity, it's necessary to partner with suppliers who deliver high-quality products. Look for suppliers that focus in rod end bearings, have a proven track record of success, and offer detailed technical guidance.

- Evaluate the supplier's knowledge in your specific industry.

- Request samples to examine the quality of their products firsthand.

- Inquire about their manufacturing processes and quality standards.

By carefully selecting your rod end bearing suppliers, you can maximize the efficiency of your industrial equipment.

Stainless Steel Rod End Bearing: Longevity and Rust Prevention

When demanding applications necessitate high performance and long service life, stainless steel rod end bearings emerge as a preferred choice. These bearings are renowned for check here their exceptional strength to corrosion, ensuring reliable operation even in harsh environments. Constructed from premium-grade stainless steel alloys, they exhibit inherent protection against common corrosive agents such as moisture, chemicals, and salt spray.

The smooth, accurate ball bearings within these rod end units facilitate low friction movement, minimizing wear and tear. This combination of corrosion resistance and durability makes stainless steel rod end bearings ideal for a wide range of industrial applications, including automotive, aerospace, marine, and construction.

Comprehending the Benefits of Rod End Bearings

Rod end bearings are essential components in various mechanical systems, offering significant advantages over traditional bearing types. These spherical-shaped bearings feature a sturdy outer housing and an inner race that accommodates a oscillating rod. Their key benefit lies in their ability to compensate for misalignment, ensuring smooth and efficient operation even under fluctuating load conditions. Furthermore, rod end bearings are known for their high load capacity and durability, making them a dependable choice for demanding applications.

- Applications that benefit from rod end bearings include:

- Transportation systems

- Production machinery

- Farming equipment

Choosing the Right Rod End Bearing for Your Application

Implementing the optimal rod end bearing in your machinery is crucial for efficient operation. A mismatched bearing can lead to premature wear. To avoid these pitfalls, consider factors like load capacity, operating temperature, and installation type. Carefully review the specifications provided by the manufacturer and consult with a knowledgeable professional if needed.

- Focus on the expected load to ensure your bearing can handle it.

- Evaluate the working conditions where your bearing will operate.

- Research different construction types for optimal performance in your specific application.

By carefully considering these factors, you can select the right rod end bearing to ensure optimal performance for your machinery.

The Crucial Function of Rod End Bearings in Precision Systems

In the realm of precision/high-accuracy/critical machinery, components must function with exceptional consistency/stability/reliability. Rod end bearings/These rod end bearing assemblies/Rod end bearing units play a pivotal role/function/part in ensuring this level of performance. They provide smooth/frictionless/low-resistance rotation/movement/pivoting while withstanding significant loads/forces/stresses. This makes them essential for applications where even minute/slight/small deviations can have detrimental/negative/undesirable consequences.

A variety of factors contribute to their effectiveness, including/Various characteristics contribute to their success, such as/Several key attributes make rod end bearings ideal for these applications:

- Durability/Longevity/Strength - Constructed from high-grade materials/robust metals/strong alloys, they can endure prolonged use and harsh operating conditions/environments/circumstances.

- Self-alignment/Angular capability/Flexibility - They compensate for misalignments between connected components, ensuring continued smooth operation/accurate movement/reliable performance.

- Low friction/Reduced resistance/Minimal drag - Minimizing energy loss and wear, they contribute to overall efficiency/performance/productivity of the system.

The widespread application/use/implementation of rod end bearings in precision machinery underscores their vital contribution/importance/impact on achieving accurate and reliable results.

Lark Voorhies Then & Now!

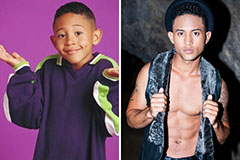

Lark Voorhies Then & Now! Tahj Mowry Then & Now!

Tahj Mowry Then & Now! Alexa Vega Then & Now!

Alexa Vega Then & Now! Kane Then & Now!

Kane Then & Now! Kerri Strug Then & Now!

Kerri Strug Then & Now!